The HopLoc® Mission

|

|

is one hop locating. HopLoc® serves location awareness. | |||

|

|

expands automatic identifying with labels and tags to automatic wireless locating. HopLoc® has an elementary prerequisite: That is scanning the moved items whenever and wherever set anew to motion: Set to road shipment, moved in intra-logistics or moved by automatic transfers. | |||

|

|

requires as an infrastructure solely some anchor transponders and the networking thereof via LAN or WLAN and becomes ready for operation on an instant. | |||

|

|

requires the tagging of the transportation vehicles with transponders and of the transported items with tags or with transponders and thereby gets immediately applicable for direct or indirect locating. | |||

|

|

then supports all tracking automatically on provided location aware scanning data. |

|

Practitioners in logistics sites know the problem of missing shipments: The item just displaced a few metres aside the collection point for destination and the shipping will go wrong. HopLoc® now helps to reduce the search times for such displaced shipments to zero, just by scanning latest at setting down. Such is generalised human experience: It is much more effective to control and much faster to convey, when acting in certainty to act on the entire shipping list in collecting, allocating to dock and finally loading to truck. Practitioners in logistics sites know the problem of missing shipments: The item just displaced a few metres aside the collection point for destination and the shipping will go wrong. HopLoc® now helps to reduce the search times for such displaced shipments to zero, just by scanning latest at setting down. Such is generalised human experience: It is much more effective to control and much faster to convey, when acting in certainty to act on the entire shipping list in collecting, allocating to dock and finally loading to truck. HopLoc®, makes searching totally obsolete, when registering every shipping item on placement not only by identity and with a time stamp, but also with the location of placement. |

|

|

supports video recording and automates video sequencing for shipping operation in a goods depot. | |||

|

|

provides proof for any lost item on the basis of directly related sequences of video records. | |||

|

|

may turn any area in a goods depot to a logistics theatre where locating any object becomes easily enforced. | |||

|

|

upports advanced data access to shipping files in conjunction with lifter displays, handheld scanners, PDAs, tablet PCs, wheeled PC mobiles as used by the logistics team in any setup of their work environment. | |||

|

|

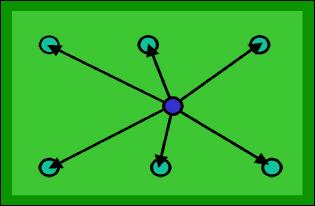

makes use of crisp locating according to ISO/IEC 24730-1: | |||

|

|

qualifies the place where the searched object resides by at least three measured distances, when HopLoc® the distance is clearly measured, the measure is well calibrated. | |||

|

|

is excellent to get the location of the mobile object in the wireless illuminated environment. | |||

|

|

makes use of a priori knowledge: In locations with limited wireless illumination and poor visibility, the location will be determined upon two distances and computed tracking data. | |||

|

|

serves inherent identity of the located transponder according to ISO/IEC 19762-5, hence HopLoc® serves as an RFID tag according to ISO/IEC 19762-3. |

Copyright © 2009 ReadPost Gesellschaft mbH